Meeting France’s Stringent New Textile Rules with BioBlack

By Nature Coatings Staff

Europe is rapidly reshaping the fashion industry with some of the strictest environmental regulations in the world. France has taken the lead by introducing its eco-score framework for apparel and footwear, set to become mandatory by 2026. At the same time, the EU is rolling out its extended producer responsibility (EPR) legislation, which will fundamentally change how textiles are designed, labeled, and recovered. Together, these laws aim to shift the industry toward circularity and accountability—but for brands, they also bring significant compliance challenges.

At Nature Coatings, we see these shifts not as barriers but as an opportunity to accelerate positive change. Our BioBlack pigment, created from wood waste, provides a direct path for brands to lower their environmental footprint while meeting emerging requirements in France and across the EU.

One of the most urgent regulatory changes is France’s eco-score system. Much like the nutrition labels that reshaped the food industry, the eco-score will grade clothing based on its climate, water, and biodiversity impacts. For brands, this means no longer hiding behind general sustainability claims—impact will be quantified and compared across products. France’s new laws are the most stringent extended producer responsibility (EPR) law for fashion, following California’s similar Responsible Textile Recovery Act of 2024.

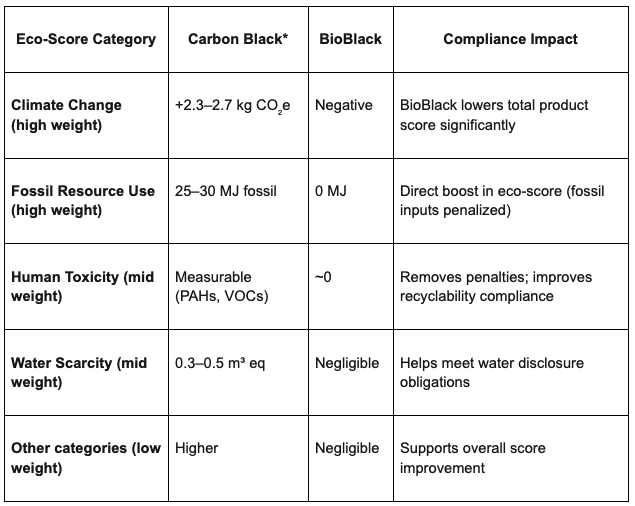

France Eco-Score (Écobalyse)

France’s textile eco-score uses a weighted index across 16 midpoint indicators, with climate change, fossil resource use, and toxicity carrying the heaviest weights.

Result: BioBlack® directly improves the three highest-weighted impact factors in France’s system. Brands can expect a visible jump in eco-score grades when substituting petroleum black with BioBlack®.

As you can see, BioBlack offers measurable benefits. Unlike petroleum-derived carbon black, which is energy-intensive, fossil-fuel based, and associated with toxic contaminants, BioBlack is 100% bio-based and carbon negative. Its use reduces greenhouse gas emissions, eliminates fossil fuel dependence, and avoids harmful substances like nanomaterials—all key factors in improving eco-score ratings.

The EU’s forthcoming extended producer responsibility system raises another set of challenges. By 2028, brands will be financially responsible for the collection, sorting, and recycling of the textiles they place on the market. Fees will be tied not only to volume but to the environmental safety and recyclability of materials.

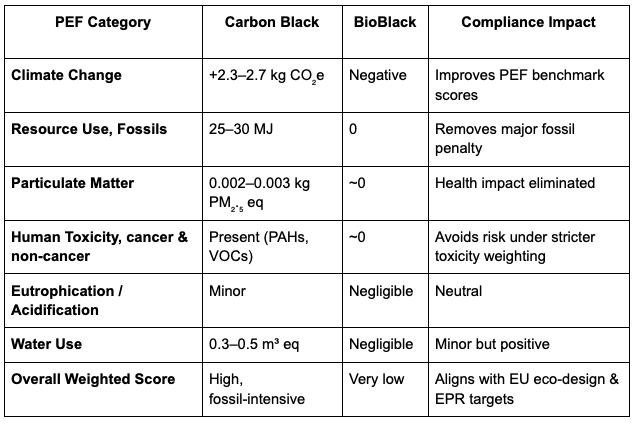

EU Product Environmental Footprint (PEF)

PEF for textiles uses 16 categories too, but with a standardized set of normalization and weighting factors across EU markets. The top policy-relevant categories are climate change, resource use (fossil), particulate matter, and toxicity.

Result: In the EU PEF methodology, BioBlack® reduces scores in the exact categories with the strongest weighting and highest regulatory scrutiny, making it a clear compliance advantage as PEF becomes the EU’s standard for textile LCA and labeling.

These changes represent more than just a legal hurdle. They signal a systemic shift in how fashion is valued and measured. Regulators, NGOs, and consumers are converging on the same demand: proof, not promises, that brands are lowering their footprint and moving toward circularity. By integrating BioBlack, companies are not only able to comply with these evolving laws but to lead with solutions that are verifiable, scalable, and safe.

At Nature Coatings, we believe compliance should not just be about avoiding penalties. It should be about creating products that truly align with the world we want to build. BioBlack is proof that the fashion industry can meet stringent regulations while unlocking innovation, improving transparency, and building consumer trust. The rules are changing—Nature Coatings is here to help you stay ahead of them.